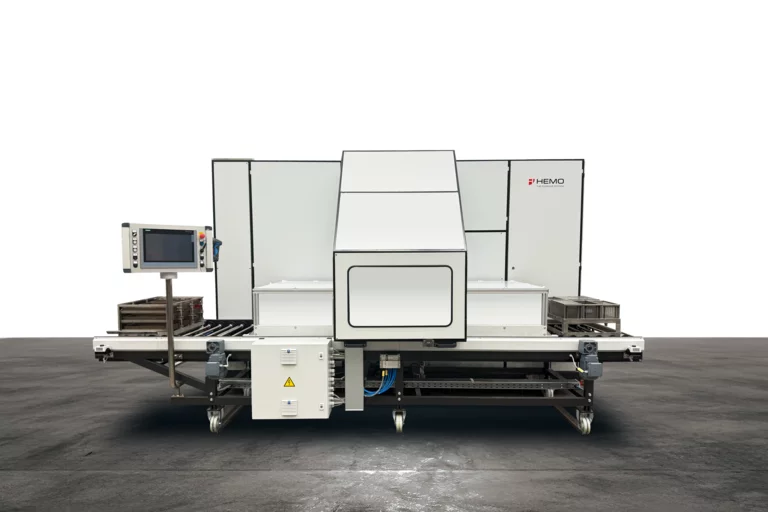

HEMO GmbH was born in 2017 out of the merger of EMO Oberflächentechnik GmbH and Hösel GmbH. The company is one of the world's leading manufacturers of parts cleaning systems for solvent and hybrid processes.

With the development of the patented VAIOCS process in 1995, HEMO set standards for safe cleaning with flammable solvents. The innovative HYBRID technology combines solvents and aqueous media in one cleaning system, enabling the highest cleaning quality for complex requirements—and has been doing so since 2000.

The Test Center is the heart of the company and the basis for its success. It provides modern and state-of-the-art standard systems for process and procedure development. Thanks to flat hierarchies and short, direct communication channels, findings from trials are continuously incorporated into the design and manufacture of the systems.

HEMO GmbH offers a comprehensive service and support area that is specifically tailored to the requirements of our national and international customers.

Get in touch with us. We will be happy to advise you and develop the right solution for your manufacturing task.

Processes

HEMO GmbH has been known and established on the market for more than three decades for its innovative processes based on solvent-based cleaning, which was patented and developed in 1995.

- VAIOCS process (since 1995)

- Patented process for the safe use of flammable solvents at temperatures above the flash point.

- Sets standards in solvent cleaning.

HYBRID technology (since 2000)

-

- Combination of solvent and aqueous cleaning in successive steps within a common chamber.

- Particularly suitable for complex cleaning requirements.

BEYOND process (since 2016)

-

- A novel approach in which solvents and aqueous media are not separated but used in a mixture.

- The goal: increased efficiency and better cleaning results for difficult applications.

Process workflow

- Loading the cleaning chamber

- Workpieces are placed in the chamber manually or automatically.

- The chamber is sealed airtight.

- Evacuation

- The chamber is set to system pressure under vacuum to remove air and moisture.

- Solvent supply

- Solvent (e.g., modified alcohol, hydrocarbons) is fed into the chamber.

Depending on the process, the solvent can be introduced as vapor or liquid.

Cleaning phase

- The workpieces are cleaned by:

- Spray cleaning

- Ultrasound

- Pressure flooding

- Stagnation, swiveling, or 360° rotation

- Steam degreasing.

- Goal: Removal of oils, greases, particles, chips, and other contaminants.

Distillation / Filtration / Treatment

- The used solvent is continuously treated:

- Distillation for recovery

- Filtration for removal of particles

- The cleaned solvent is returned to the process.

Drying

- The cleaned parts are dried under vacuum.

- Solvent residues are completely removed.

Ventilation and removal

- The chamber is ventilated.

- The clean and dry workpieces are removed.